Blog Archives

When and Why Ion Nitriding/Nitrocarburizing Makes Good Sense

When and Why Ion Nitriding/Nitrocarburizing Makes Good Sense

Advanced Heat Treat staff Dr. Edward Roliński and Gary Sharp authored this article from Industrial Heating magazine, August 11, 2005:

Ion, or plasma, nitriding has been studied and used industrially for more than 40 years [1-8], but the technology has not been used to its full potential. Ion nitriding/nitrocarburizing is a low temperature (800-1100˚F, or 430-595˚C) process, which results in little or no distortion of the treated parts even if significant residual compressive stress is induced to the surface layer of the treated products. The ion nitriding process also has been referred to by other surface treating characteristics including plasma, vacuum, diffusion, low nitriding potential, passive surfaces activating, easy-to-control structure and pollution-free processes. These process characteristics with the exception of the low nitriding potential concept are discussed in the literature.”

Click here to read the entire article:

http://www.industrialheating.com/Articles/Feature_Article/f022e50797cb7010VgnVCM100000f932a8c0

Learn more about the authors here www.ahtweb.com

Gas Nitriding/Gas Nitrocarburizing

Gas Nitriding or Gas Nitrocarburizing is a case-hardening process whereby nitrogen is introduced into the surface of a solid ferrous alloy by holding the metal at a suitable temperature in contact with a nitrogenous gas, usually ammonia.

Benefits include:

- Extends part/tool life

- Adds performance, fatigue strength and endurance

- Enhances surface lubricity

- Reduces erosion

- Increases material flow in molds and dies

- Improves corrosion resistance

- No post-process machining

- Improves wear resistance

- Zero to minimal growth/distortion

- Precise and versatile

- Phase controllable compound zone

Recommended for:

- Stainless steels

- Tool steels

- Powdered metals

- Medium carbon steels

Learn more at: www.ahtweb.com

Nitriding and Nitrocarburizing

Nitriding/Nitrocarburizing Types:

- Ion Nitriding (Plasma Nitriding / Nitrocarburizing)

- Gas Nitriding (Gaseous Nitrocarburizing)

- Salt-Bath Nitriding (Liquid)

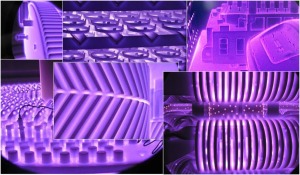

Photo of Ion Nitriding:

Induction Hardening

The Burton facility in Waterloo, IA is the oldest Advanced Heat Treat Corp. location and specializes in UltraGlow Induction Hardening, Carburizing, Carbonitriding, Stress Relieve, Quench & Temper/Through Hardening, Annealing, Normalizing, Cold Treatment, Oxidation Treatment, Duplex Hardening, Assembly, Cleaning Applications, and MUCH MORE! Here’s a photo of a part being induction heated:

Induction hardening is a method of heating electrically conductive materials to a temperature within or above its transformation range by means of a varying magnetic field. This process generates a voltage which has the ability to create and electric current that dispels energy and produces heat by flowing against the resistance of an imperfect conductor. After the metal is heated, it is immediately quenched. Induction hardening results in a hardened case while the core of the part remains unaffected.

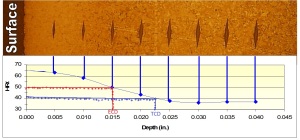

Case Depth Terms

When applying a heat treatment, such as ion nitriding, to a part, it is important to know the following case depth terms:

Effective Case Depth (ECD):

The distance from the surface of a hardened case where a specified level of hardness is maintained (typically 50 HRC eqv.).

Total Case Depth (TCD):

The distance from the surface of a hardened case to a point where differences in physical properties of the case and core are no longer distinguished (visual or hardness method).

For example:

For more information, visit www.ahtweb.com.

For more information, visit www.ahtweb.com.

What is Heat Treat?

Heat treat is a process in which a material is heated and/or cooled in a particular manner to alter its mechanical properties such as hardness, tensile strength, yield strength and fatigue strength. Learn more at www.ahtweb.com.

Honda To Expand Production Of Light Trucks, Engines At Alabama Plant

Honda To Expand Production Of Light Trucks, Engines At Alabama Plant.

Bloomberg News (11/15, Ohnsman) reports, “Honda Motor Co., Japan’s third- largest automaker, will spend $84 million and hire 100 more workers to expand production of light trucks and engines at its assembly plant in Alabama.” In a statement, Honda said that “the investment will boost annual capacity for the Lincoln, Alabama, plant to 340,000 vehicles and engines by 2013 from 300,000 now.” Bloomberg News notes, “Asian automakers including Honda are expanding output capacity in North America as US sales recover from a recession in 2008 and 2009. Demand for new cars and trucks grew 10 percent this year through October, and most companies and analysts are forecasting total sales of 12.5 million to 13 million vehicles in 2011.”

The AP (11/15) reports, “The $1.5 billion plant began production with the Odyssey minivan. The plant employs about 4,000 people and is the sole North American producer of the Odyssey, the Pilot SUV and the Ridgeline pickup.”

The Birmingham Business Journal (11/15, Poe, Subscription Publication) reports, “The latest investment, which brings Honda’s total investment this year up to $275 million and 140 jobs, is tied to the addition of the Acura MDX luxury SUV to the plant’s production lineup, the company said.”

On its website, WLTZ-TV Columbus, GA (11/15) notes, “In 2013, the Lincoln plant will start making the luxury Acura MDX sport utility vehicle.”

Also covering the story are the Anniston Star (11/15, McCreless), WVTM-TV Birmingham, AL (11/15, Jackson) and other media sources.

Read the article here: http://www.businessweek.com/news/2011-11-16/honda-expanding-alabama-plant-to-lift-light-truck-engine-output.html

Did you know Advanced Heat Treat Corp. has a location in Alabama?

The Cullman Facility is located at: 1545 County Rd. 222 Cullman, AL 35057 and specializes in heat treat services such as: Ion Nitriding, Ferritic Carburizing, Stress Relieve, Oxidation Treatment, Duplex Hardening, Assembly, Cleaning Applications, Metallurgical Services & Consultation, Tempering/Drawing, Polishing, and Failure Analysis.